Maintaining quality while keeping production costs low is one of the key challenges faced by manufacturing companies. When it comes to cost savings, immediate areas that manufacturing companies look at are cutbacks (in resources, technology, etc) or major overhauls and experiments in operations and processes which can negatively impact the performance and require costly investments, allowing your competitors to get ahead in the meantime.

The traditionally overlooked areas that contribute continuously to the cost in any industry are the quality and intermittency of resources, procurement and supply chain challenges with high lead times, installation, and tedious inventory management. If you are an industry that uses process heating and are keen to explore how you can save huge costs in your production without overhauling your existing processes, this 5 minutes read will definitely provide the solution to your problem.

Keeping in mind our customers’ pain areas, we at Nexthermal have designed Nextflex tubular heaters. Nextflex is specifically designed to help companies save cost with quality, simplified supply chain, easy procurement, installation, and inventory management. Check out how a simple switch to Nextflex tubular heater can help you save money in the 5 critical areas of manufacturing below:

1. Saving with Quality – Better Heat performance

Nextflex has one of the lowest bending radii (6.5 – 10 mm) in the industry and can be formed in virtually any 3D shape. This gives you the ultimate flexibility to reach parts of the mold that were earlier not possible. Essentially, you get to bring heat to areas you couldn’t before!

Nextflex is made with high-grade Nichrome resistance wire at its core, insulated with MgO and copper, with flexible nickel sheath on the outside. Essentially assembling all into a composite structure that provides flexibility for forming into complex shapes that provides optimal thermal conductivity! Copper also helps with drastic improvements with the temperature difference in the mold. Furthermore, the outermost stainless sheath covering provides oxidation resistance at high temperatures. This also helps us pack higher watt density and thereby giving higher temperatures as opposed to a traditional tubular heater.

In short, Nextflex is designed and built for better heat transfer, better heater life, and thereby a much superior performance!

2. Saving with Simplified Supply Chain

In today’s uncertain times, companies face many challenges in the supply chain with demand variability, extended response times, and also long delays in shipments especially while procuring from overseas. All this adds to procurement challenges which eventually causes more harm and cost to the business. Nextflex is proudly designed and assembled in the United States, which is one of the reasons why we are able to ship you the product with same-day shipping!* (if ordered before 2:00 PM EST)

Furthermore, with 170+ unique combinations for lengths and diameters, whatever your mold, chances are we already have a solution in stock for you! If not, there is no size we cannot do!

Thereby saving you precious time loss due to delays in logistics and supply chain, Nextflex can save your costs with a ready-to-ship solution with same-day shipping anywhere in the world!

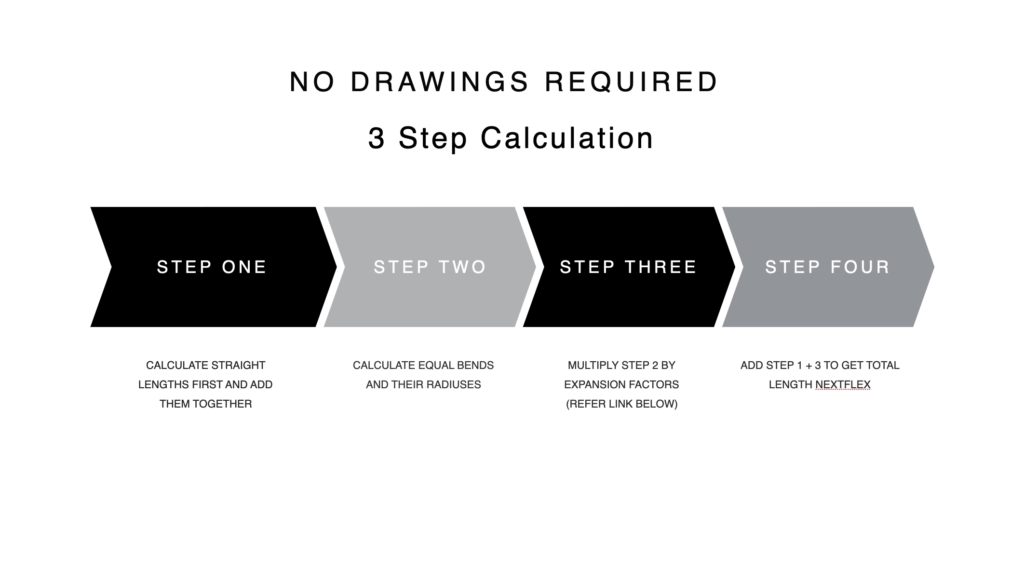

3. Saving with easy procurement and design

No drawings required! Yes so you can skip the time lost in back and forth in drawings and approvals involved while procuring tubular heaters! Moreover, it’s super simple to calculate the size of the heater that will fit your manifold with 3 easy steps!

STEP 1: Calculate straight lengths and add them together

STEP 2: Calculate equal bends and their radius

STEP 3: Multiply step 2 by expansion radius

STEP 4: Add step (2*3) + 1 to get the total required Nextflex length!

You can also refer calculations and groove size determination here

4. Saving with Inventory Management

Inventory management is a common problem in manufacturing companies given the ever-changing market demand. Carrying too much inventory for a product can be costly as it adds to the storage costs until the product is sold. Alternately, carrying too little can hurt your production timelines if there is a sudden surge in the market demand and eventually still add to your costs.

What if you are able to offload part of this inventory management? That is where we come in. We will always keep your inventory in stock with us so that you can order as and when you see fit and we ship you the product the same day. That way, you can save on inventory costs and maintain flexibility in schedule.

5. Saving with easy Installation

Many times, while procuring heaters from the market, companies also have to invest in special labor costs for complex installations. With Nextflex, you don’t have to invest in special labor skills, as it can be done by anyone and still get a perfect install every time. To make installation simple and easy, we also provide dead blow hammer, staker, and ‘former’ that are simple to use and effective. You can also watch Nextflex installation videos with a click of a button right from your mobile device at this link

In summary, Nextflex can be a powerful solution to help you improve your heat performance as well as reduce your total cost of ownership! Nextflex heaters can be used in any industry that uses heat – manufacturing, plastic injection molding, rubber injection molding, aluminum extrusion, packaging – food packaging, medical packaging, blister packaging, 3D printing, etc

A simple switch to Nextflex is all you need to unlock huge savings in critical areas of your production!

If you wish to learn more, watch our webinar on Nextflex at this link!

Contact us at Nexthermal below!

Phone: +1(269)-964-0271

E-mail: sales@nexthermal.com

Want to evaluate how Nexthermal can help solve specific heat problems in your application? Or just interested in knowing more about Nextflex? Feel free to reach out to us through the form below and one of our team members will reach out to you soon!