Custom Food Packaging

Challenges in Form-Fill-Seal

- Experiencing high number of leakers?

- Do the heaters fail pre-maturely within 3-6 months of installation?

- Is there high movement or moisture in the application?

- Is it a washdown application?

- Multi-layer or green films?

- Need hygienic design?

- High scrap rate?

- Slow throughput?

Optimize Your Packaging Process

As a manufacturer that uses packaging machines, you know that keeping equipment running efficiently is critical to improving food production, increasing throughput, and reducing scrap. Today’s packaging materials are less forgiving of temperature variations, and throughput speed is dependent on fast heat recovery. You need solutions that address these challenges to stay competitive and profitable. Nexthermal Engineering Services can analyze key process areas and identify where problems exist. With our expertise in the packaging industry, we can help you turn a problem process into a profitable program.

Designed for Energy Efficiency

When heat is essential to your process, you need a high performance system that is specifically designed to support your core application goals. Energy efficient design practices combined with emerging heaters energy efficient heaters have helped our customers realize energy savings of 15-35% with the same or improved performance levels.

Challenges in Top Seal packaging

- Issues with sealing new material due to FDA-required changes?

- High temperature variance in the heat profile?

- Limitations on material selection for your current machine?

- Design restrictions by your current heater supplier?

- Excess scrap?

Nexthermal can partner with you to solve these challenges while still allowing you to continue using your current equipment. We can retro-fit heaters into your top-sealing machine allowing you to control the heat profile to reduce scrap and expand your material selection.

Case Studies for Top-Seal Applications

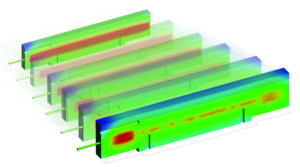

Due to FDA regulations and the want to become more environmentally friendly, many of our partners have switched the material and film used for their top-seal packaging. In the process, they have found difficulty in making a proper seal. They were experiencing a ∆T of 40°F on their heat profile. By using thermal analysis, Nexthermal was able to design a heater with a better temperature profile to retro-fit into their existing machines. The new design brought the ∆T to under 4°F. This gave them the flexibility to use different materials and save on having to purchase a different top-seal machine.

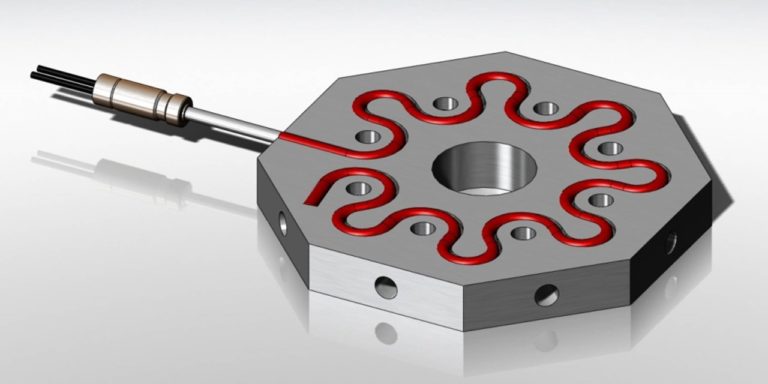

Convenient Turnkey Solutions

Nexthermal has engineered a thermally profiled top sealing heater that can be tailored to your process. You benefit from our extensive R&D and thermal analysis with an optimized top seal system that can be modified to fit your equipment. Nexthermal can respond fast to your requirements with a proven design customized to improve your process efficiency.

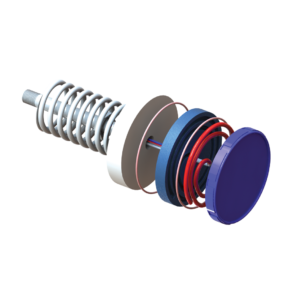

Round Formable Coil Heater

Size & Shape Versatility

Faster Thermal Recovery Improves Speed and Seal Quality