Electric heaters are resistance wires that use thermal energy to raise an application’s temperature as required for optimal processing. Heaters are used for different industrial operations like induction heaters, coil or cable heaters, tubular heaters, and immersion heaters. Some heaters need to be fitted or mounted, while some can be used as a stand-alone device.

What are Coil heaters?

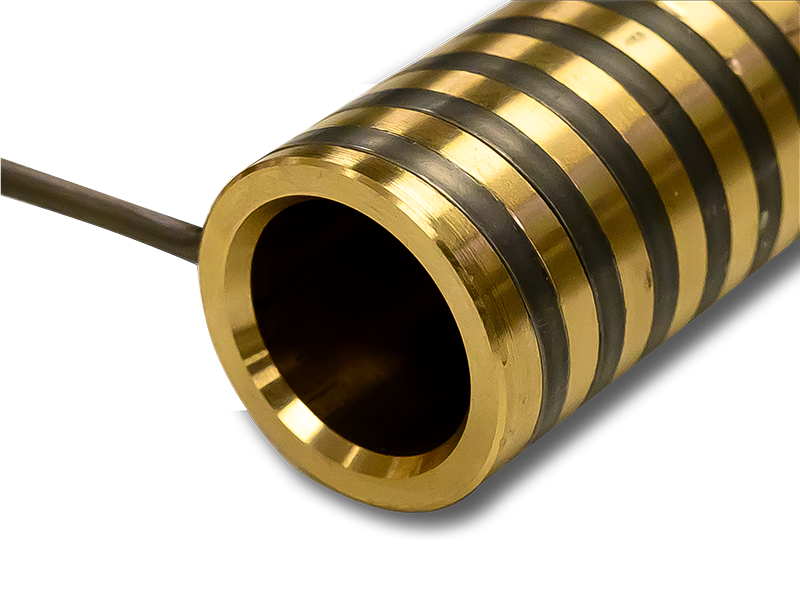

Coil heaters are used to predominantly heat hot runner nozzles, small hot runner manifolds, smaller plates for rubber injection molding or rubber compression molding, any application where a 3D-shape is required in a smaller space, formed in a groove where heat is needed around cut outs and holes, and also for liquid heating. They are also seen as small tubular heating devices.

They can be formed into any geometrical shape based on their industrial application and the type of process they are used in. Coil heaters can be made into straight lengths, spirals and other patterns. This flexibility allows them to be fitted in multiple applications. Coil heaters are also referred to as cable heaters or spring heaters.

Cable heaters can be coiled into a small nozzle heater to enable 360 degree heating with distributed wattage. The coil type nozzle heaters are specially designed to minimize heater failures due to leakage and plastic contamination near the nozzle. Nexthermal is UL approved for coil heaters and cable heaters.

Heating coils that are used in everyday appliances are made from nichrome, which contains nickel and chromium alloys. Wires made of nichrome are used in heating coils, specifically because of their flexibility and their high melting point.

Common Applications of Coil Heaters

Coil heaters are widely used in common household appliances and also in large industrial applications such as:

- Hot runner nozzles

- Small hot runner manifolds

- Small heating plates for rubber injection molding

- Rubber compression molding

- Food packaging jaws for form fill and seal applications

- Analytical equipment as a heat source to catalyze

- Testing equipment in medical / plastic industries

- Lab equipment for liquid heating

- Pipe heaters

- Plastic injection molding machines and nozzles

- Food and candy specialized extruders

- Bag sealing

- Hot stamping

- Packaging equipment.

Advantages of Coil Heaters

- Coil heaters can be formed into any geometrical shape

- They can withstand high levels of heat as they are coiled

- They are rust-resistant, which makes these heaters highly durable

- Coil heaters are easy to install and are economical

- Coil heaters perform well in small places where high heating and performance is crucial

- They provide accurate temperature control and a fast response time

Nexthermal’s Wide Range of Coil Heaters

Nexthermal offers an extensive range of coil heaters which are precise, durable and versatile. Our proven manufacturing process uses high quality materials and state-of-the-art manufacturing techniques to develop heaters that suit your specific application and ensure maximum process efficiency. We also design and develop custom heating solutions based on your unique needs.

Nexthermal coil heaters come with both internal and external thermocouple options. For higher temperature applications, Nexthermal can manufacture long, unheated flexible sections with leads that are moisture resistant.