Struggling to reduce your energy consumption in the manufacturing or packaging industry ? Do you have production capacity and power constraints? Looking for simple solutions to achieve your energy goals without having to overhaul your entire operations ? Let us show you how Nexthermal’s coil based top seal heater can help you save big on your energy costs.

Today, businesses are faced with regulatory requirements and competitive pressures to reduce energy footprint while maintaining profitability. Manufacturers need to look closely for opportunities to reduce energy consumption in overall operations. That said, there are several critical activities in production that consume a ton of power and are at the heart of the operations.

Process heating is a common area amongst the majority of industries that may account for up to 38% of the total energy used in industrial plants. This is where we at Nexthermal have successfully created an impact by designing efficient heating solutions that can help reduce overall energy consumption. Nexthermal is an industry leader in industrial heating solutions. With 35 years of industrial experience under our belt, we are dedicated to designing solutions that can optimize the efficiency of the system, increase throughput as well as save you energy!

Using the right heater design customized to your application could be all that it can take to unlock your energy-saving opportunities!

Customer Success Story:

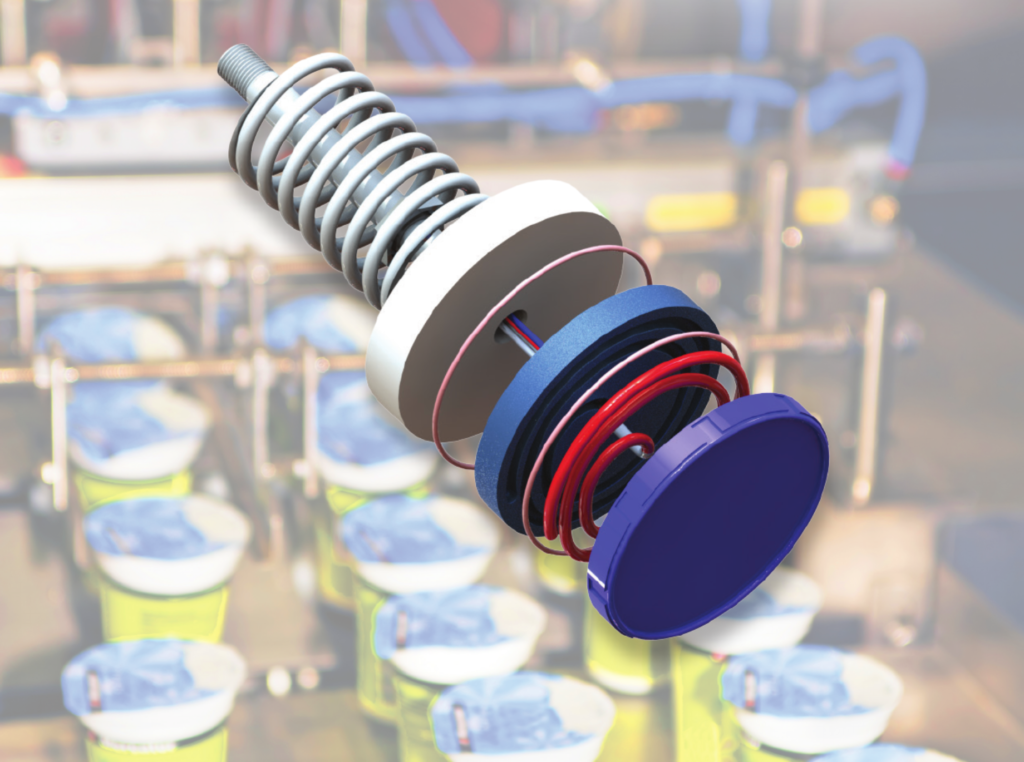

Nexthermal specializes in custom design for top seal and tray seal applications. Some of these designs have specifically helped our customers save up to more than 40% energy!

How would you like to double the machine output, with the same energy consumption?

For one of our customers, we redesigned the top and tray seal heating assembly for one of the world’s largest packaging machine manufacturers whose market goal is to help leading food brands in North America to stay competitive. During the design review meetings, we discovered that the wattage requirement typically assigned by the customer was too high to be able to control accurately. So during the design phase, we used our thermal simulation tools to quickly analyze proposed designs with reduced mass that reduced the power requirement significantly (from 650 Watts to 440 Watts). These design changes allowed an extremely efficient top seal design, maximum machine throughput, and overall energy savings opportunities.

The customer was now able to produce double the seal heads with the same amount of power than before, thus increasing productivity by a whopping 100%

What, you think what you have is the best way already?

Accurate heat and control is extremely crucial in food and dairy packaging to ensure a quality seal. Furthermore, in today’s hyper-competitive market, the ability to produce packaging with different shapes and sizes can make or break your competitive advantage and brand differentiation. But how do you achieve this with the same quality seal or even the ability to seal with your existing assembly? Nexthermal specializes in working with the customer to custom design the top seal and tray seal applications. Our top seal and tray seal design can leverage coil heaters, cartridge heaters, or even Nextflex heaters (which is our new flexible tubular heater) to suit your application and needs for packaging – even for different shapes and sizes!

What you never thought possible might be with the wide range of design options Nexthermal can offer

Nexthermal identifies the need for businesses to be sustainable in the way they operate and produce and is determined to walk with you on the sustainability journey. While many of our customers are dedicated to finding sustainable alternatives, our top seal design assembly caters to just that! It is fit to be used for environment-friendly films, green films with excellent seal quality every time! Design for purpose is in our philosophy while designing any solution!

You can learn more about Top Seal heaters through our recent webinar on Optimizing Top Seal Solutions

In addition to the improved heat transfer and energy savings with a top seal, you can achieve considerable savings with

- Super fast and Hassle free procurement: Get quotes within as soon as 2 Days

- Easy Installation: Our coil heaters can be hand bent into the application thereby eliminating the additional cost on installations!

Other Packaging Applications that Nexthermal has expertise in:

- Form Fill and Seal

- Portion Packaging

- Steam Shrink Sleeve Packaging

- Thermoformed Packaging

- Bottle Packaging

- Blister Packaging (can provide expertise in this area as well)

In conclusion, if you are keen to explore how you can unlock your energy savings potential, contact us today!

To learn more about our top seal heaters, heater assemblies or just want to check out how Nexthermal can solve your heat specific problems leave us your information below