Struggling to achieve 100% leak proof sealing in your top seal packaging? Unable to welcome new materials or creative shapes in your packaging? Or having to do major overhauls to your existing application assembly for new changes? If you are in the food packaging industry using top seal packaging, this 10 minutes read is a must!

When it comes to packaging food and beverages, top seal packaging is a popular choice, be it amongst frozen foods packaging, dairy and yogurt packaging or even as recently seen trending it’s way into produce packaging. Consumers seem to prefer top seal packaging even more than other traditional forms of packaging due to numerous potential benefits such as:

- More Product Visibility of the product with clear, transparent nature of the packaging

- Increased Shelf Life with better freshness

- Product Safety

- Clear product damage or tamper evidence

- Potential for better sealing

- Variety of eco friendly, sustainable film options

- Boosts less packaged (feel-good) notion about the product in customers

- Volume of the packaging materials is considerably less

That said, not every top seal packaging can provide all of the above. As the market and environmental conditions are fast changing the top seal packaging industry has faced challenges on multiple fronts contesting some of the benefits listed above. For example:

- Issues on achieving 100% sealability or leak proof sealing

- Issues with using newer material such as eco-friendly films for sealing

- Issues in top seal application requiring various shapes with existing assembly

Whatever the challenges, we at Nexthermal can help resolve those for you to achieve optimal results from your top seal packaging. Nexthermal is an industry leader in industrial heating solutions and develops products for markets like yours where heat is essential to performance. From top seal heaters to top seal heater assemblies, we have engineered thermal solutions that cater to a range of packaging applications and have help several customers overcome the challenges and achieve several of the benefits of the top seal technology. Additionally, with the help of our termal engineering services and thermal expertise, our customers have benefited the freedom of experimenting and using different materials irrespective of the shapes and sizes with better sealing and increased throughput! – All with their existing assembly!

Intrigued?… Let’s take a closer look at how our heaters/thermal solutions have helped some of our customers’ in their top seal applications

1. Food Safety with leak proof seal

Food safety with top seal packaging is absolutely essential. A proper seal not only ensures to maintain the freshness of the food that the end customer consumes but also ensures maximum safety from contamination. Even the smallest leak in the packaging will allow the crucial food-preserving gases to escape and leave the product prone to contamination and thus reducing shelf life (especially foods like meat, dairy, and other frozen foods). Many times these leaks are attributed to uneven heat transfer to challenging areas of the top seal applications. Nexthermal’s heating elements and assemblies are designed to achieve uniform heat transfer to the most challenging areas of your application to ensure complete, leak proof sealing – 100% Sealed!

2. Flexibility to use various films without overhauling the existing top seal assembly

Due to the new EPA and FDA requirements, many of our customers were keen to become more environmentally friendly by switching to more sustainable material of films for their top seal packaging. However, in their process, they were facing challenges in achieving a proper seal with this new film. The customer was considering changing the assembly and purchasing all new top seal machines to accommodate this change. We evaluated the thermal profile and found out that they had a ∆T of 40º F. Through our thermal analysis, we designed a heater with a better temperature profile. This new design not only helped significantly bring down the ∆T to 4º F but also retrofitted their existing top seal assembly! Thereby enabling huge savings for the customer by not having to purchase a new top seal assembly altogether!

So whatever your film, we can design thermal top seal solution catering to the required tolerance for your application

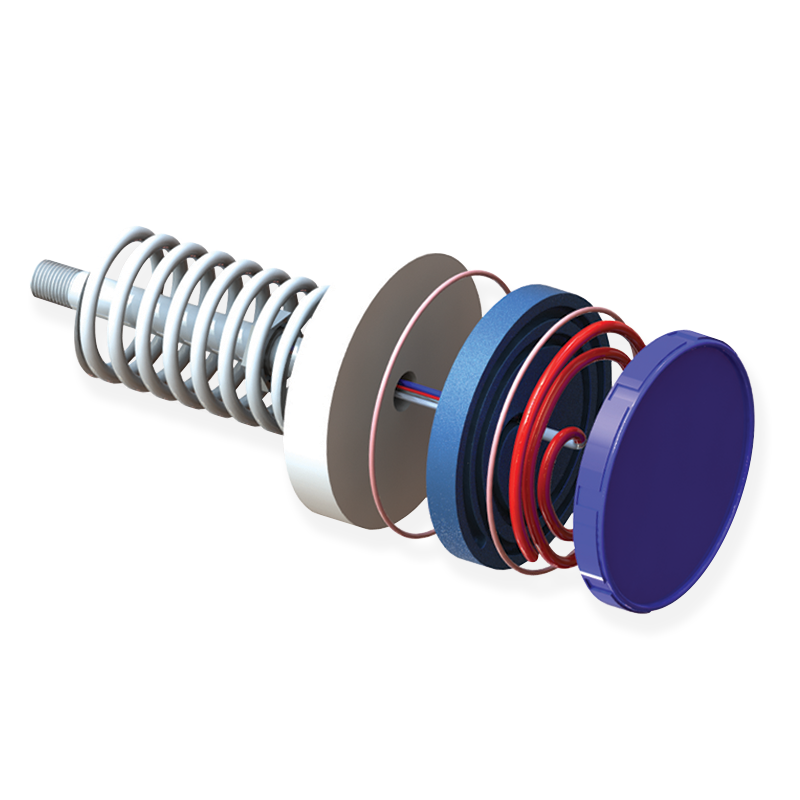

3. Enhance Heater life in food packaging applications using wash down cycles

How often do you have to change your heaters? (within a few months? – that’s more than likely attributed to moisture leak)

Most of the food packaging factories have a wash down cycle. A wash down cycle essentially refers to running hot water to wash the machines in use once or multiple times a day. These wash down cycles are a crucial part of the process as food manufacturing especially for dairy products, ice creams, etc where it can get a bit messy while packaging and need to be cleaned periodically. However, many food manufacturing/packaging plants or factories may not be temperature controlled. Which means they tend to get very humid especially during summer times. This humidity along with the hot water (from frequent wash down cycles)

seeping into the heaters, causes the heaters to fail prematurely. Thereby causing frequent heater replacements and additional costs.

Being the experts in thermal solutions, along with great products, we also believe in providing thought leadership to our customers in their applications of heat. Heat shrinks can be a good solution to keep moisture out of your heaters. As a solution, we often offer to wrap our heaters in heat shrinks before we ship them to the customer so that they don’t have to do it every single time! Thereby helping our customer overcome some of the process attributed issues and increase the heater life.

4. Customized solution to your unique process and shape/sizes requirement

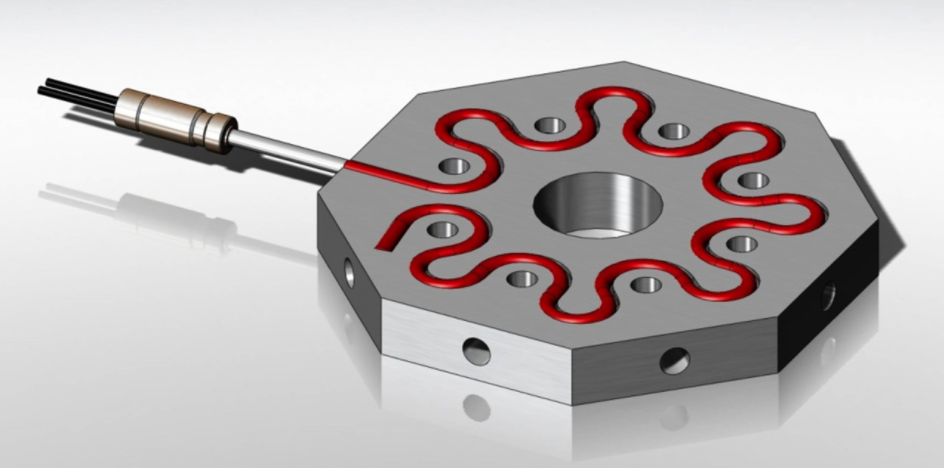

Just like a product, it’s packaging also speaks a lot about the brand and appeal of the product. As such making creativity in packaging is a necessity for acquiring that competitive advantage in today’s market! To support this creative packaging with various (and often complex) shapes and sizes, Nexthermal’s coil heater-based top sealers are the ultimate choice! The Nexthermal coil heater-based designs allow you to put heat more precisely where it is needed, ensuring you get more creative with the packaging you desire without having to compromise on the sealability or cost of additional machinery!

5. Faster Thermal Recovery and significant Energy Savings

In many cases, your top sealer mechanical equipment can run faster than your current heater will allow. Nexthermal top sealer assemblies utilize a coil heater that can be formed into a groove—putting the heat where you need it. The heater is compact, so the sealing face or sealing tool can have less thermal mass and recover quickly. Integrating machined insulation isolates the sealer from heat sinks and reduces heat loss. The result is faster, more uniform heat recovery, optimized throughput speed, and a quality seal!

We have helped some of our customers achieve a 30% – 40% reduction in energy consumption with our top seal heater assemblies and design!

We at Nexthermal, help our customers develop new products, improve process efficiency, energy efficiency, and elevate performance and quality. Identifying heater placement, sensor placement, wattage distribution, unique wattage design, minimizing heat sinks, anticipating performance issues, and solving them before you build your prototype while also helping you minimize cost with accelerated development, are all critical to your business and is what we do best!

With our Thermal Solutions Group, we can design, simulate, source, build, test, and install the thermal solution you need to accelerate your innovation.

Want to evaluate how Nexthermal can help solve specific heat problems in your top seal application? Or just interested in knowing more about our top seal heaters?

Contact us at Nexthermal below!

Phone: +1(269)-964-0271

E-mail: sales@nexthermal.com

Just leave us your information below